Turning Machines Ideal for Producing Parts from Barstock

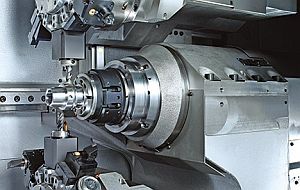

The INDEX C100 and C200 production turning machines open up new opportunities for highly productive turning of parts from bar stock. Despite their compact exterior dimensions, both machines offer a spacious working area for the complete machining of workpieces.

The INDEX SingleSlide guide system ensures very high dynamic response with optimum vibration damping. This provides impeccable workpiece quality, extended tool life and reduced cycle times, according to the company.

The vertical design of the machine bed guarantees optimum chip removal and ready access. 2 x Y axes on the main-spindle or 1 x each on the main and counter spindles are possible. This allows an optimum division even of complex operations and a reduction of cycle times.

With the optional robotic cell iXcenter, blanks and/or finished parts can be supplied and discharged quickly, safely and flexibly. The robot cell is integrated ergonomically into the machine. It can be moved easily to the right during the set-up process, allowing unobstructed access to the work area.

During production, the iXcenter is fixed in front of the machine's work area. The robot then accesses the work area via the sliding guard of the machine, which opens automatically behind the robot cell.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::